Top 5 Advantages of Using a Merlo for your Mining Operations

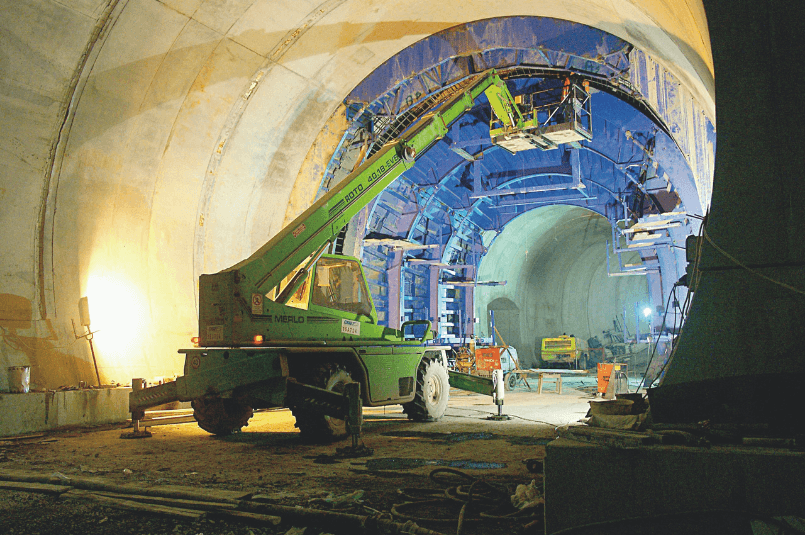

Telehandlers can be an integral asset for underground and surface mining operations. With its power, versatility and constant innovation, Merlo offers a diverse range of machines that immediately help a mining project optimize its operations. From compact telehandlers perfect to fit in tight areas to larger, more powerful options, these machines can help any mining operation.

Here are 5 reasons to trust a Merlo telehandler for your mining projects!

1. Versatility

Merlo machines have become as popular as they are thanks to their versatility. These telehandlers can replace the need for other machines thanks to their versatility and ability to complete those tasks more efficiently than the competition.

With various attachments, the most common applications are included: handling of equipment with forks, work in height with carrycot, installation of electrical cables in tunnels, submersible pump retraction, snow removal with a bucket and installation of beams with a winch.

The versatility of the Merlo telehandlers includes their attachments. Buckets, forks, baskets and the “Tyre Handler” can be put to work thanks to the Merlo Quick Attach function that allows you to switch between attachments with ease. This will save you time and increase productivity.

2. Visibility

Merlo telehandlers are designed to make life easy for operators with its 360-degree visibility. With the low mast built to the right of the cabin, these telehandlers have no blind spots. With this increased visibility, operator’s awareness of their surroundings improve.

3. Safety

Above anything else, Merlo’s commitment to innovation starts with the safety of its telehandler operators. Safety is an essential part of mining operations. The majority of telehandlers on the market have components that can harm and endanger miners.

The exclusive Merlo Dynamic Control System automatically detects the type of attachment being used, its geometric configuration, the angle of the mast and the weight of the load.

The anti-tipping system is also an essential asset. All the machine’s information is displayed on the LCD, which allows the user to operate the telehandler easily and safely. The independent stabilizers help the machine to work on uneven terrain. Speaking of stabilizers…

4. Working from the Basket

Working at tall heights inside a basket is common in mines, so minimizing movement is crucial. Merlo’s independent stabilizers are compact and robust, mounted on individual axles able to adjust to any terrain, making work at heights even safer.

Merlo’s basket with remote-control capabilities allows the user to operate the machine while working in the basket! These telehandlers have booms that reach up to 115 feet and can pivot 180 degrees to work parallel to the wall and reduce repositioning. Merlo machines use their exclusive feature, the Side-Shift, capable of moving the mast 1.5 feet to the side in both directions to limit repositioning,

5. Accuracy and Manoeuvrability

Merlo builds telehandlers that are more precise and manoeuvrable than the competition. Their compact design plays a large role in this. Its perfectly calibrated chassis, compactness, tight turning radius are just some handling functions that give Merlo the advantage against other machines.

Mining operations can see massive productivity gains thanks to Merlo’s hydrostatic transmission. These features ensure that you can adjust your movements and load position to the millimetre.

To learn more about Merlo telehandlers, click here!

For more information on Merlo and mining projects, click here!