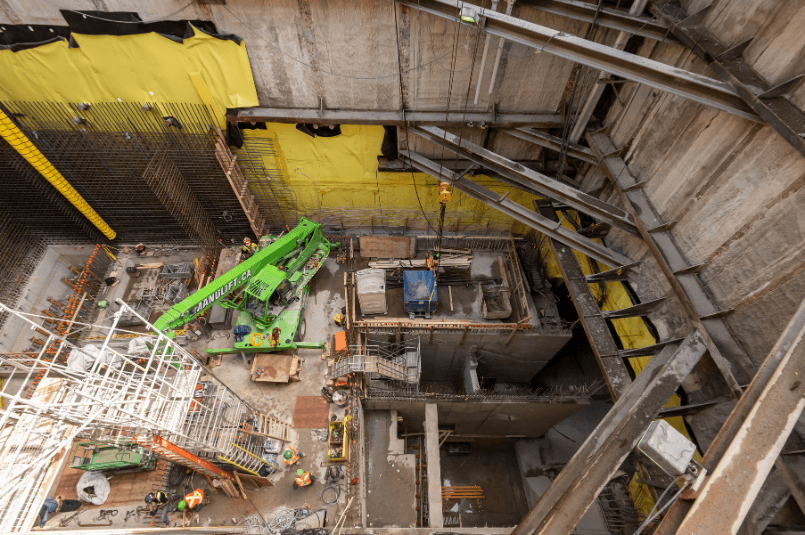

Merlo: The telehandler of choice to build the massive Eglinton Crosstown LRT project in Toronto!

The Eglinton Crosstown LRT is a massive public transit project that will provide a new east-west connection through Toronto, with 25 new stations, 10 of which will be underground. Spanning 19 km, the new light rail line will help commuters get across the city 60% faster than the current travel time.

The project — under the supervision of the design and construction consortium Crosslinx Transit Solutions (CTS) — has been quite an undertaking for many contractors and machinery operators in the city. Made up of parent companies ACS-Dragados, SNC-Lavalin, AECON and EllisDon, the consortium has been tasked with ensuring the Eglinton line is built as quickly as possible.

We spoke with Luis de España de Castro -Equipment Manager at CTS to discuss the massive project about how Merlo telehandlers are being used on the project. From the equipment on the ground to its meaning to locals, we covered a lot of the blueprint.

Due to the location of the project, Luis explains that there is very little room for error. There are constant factors that they need to keep top of mind for the safety of riders. With almost 3 million residents, Toronto requires a high level of security for a project of this size. Having reliable and high-quality equipment is always a vital aspect of the job, but in projects like these, it’s critical. “With the rules and safety regulations, we must keep all excavations covered due to the conditions of the soil.”

Equipment Journal: Eglinton Crosstown demonstrates the versatility of Merlo telehandlers

He explains this is because any exposed excavation can result in flooding or other types of damages. Therefore, they are very selective with the equipment used on their sites while looking for ways to maximize the usage of all their machines. Their fleet comprises six Merlo telehandlers; five Roto 60.24 MCSS and one Roto 45.21 MCSS.

They are primarily used for three categories of applications:

- Material handling and transportation

- Installation of ventilation systems or lighting fixtures

- Tunnel grouting

Luis highlights that the machine’s 360 rotation gives them much-needed versatility and manoeuvrability, perfect for tunnel and excavation applications. The Merlo slewing platform — which can be controlled from the platform itself — can hold up to 1,000 kg, as well as rotate to work on walls.

They’ve broken it down to a science and have a set process in place – they run shifts in teams of two, so the telehandlers are in use all day long. Thanks to Merlo’s ease of use and precision, they could train quite a few workers to operate the machines. Luis said that operators have preferred using the Merlo telehandlers over other machinery they have on-site.

Keeping the project running smoothly during such an unprecedented time was critical for CTS. Merlo’s efficiency has helped provide stability to their worksites and projects.

Merlo telehandlers continue to rise in popularity in the construction industry with a proven advantage for on-site material handling, lifting, excavation, working in tight spaces and tunnel applications. Their versatility, compactness and precision make it the telehandler of choice for operators everywhere. The Eglinton LRT project is estimated to be completed by the end of 2022.

Visit manulift.ca/crosslinx for more information and video.